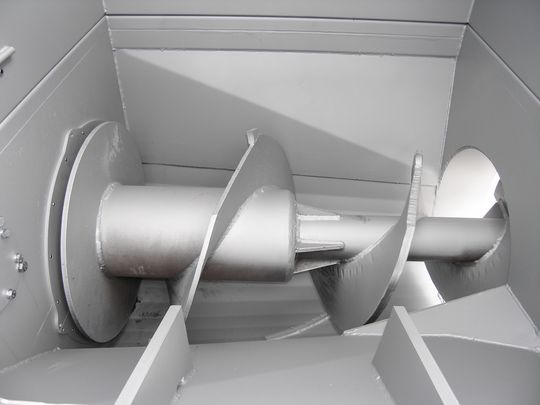

Static screw compactors

Highest compaction for maximum savings

Your optimal disposal concept for expansive material: The powerful gear motor in combination with an optimal chain drive achieves an extremely high degree of compaction. Thus, your discharge costs are reduced to a minimum. In addition, the constant rotational movement of the screw shaft guarantees a continuous filling.

AVOS SSP80 screw compactor

Product and video for AVOS SSP80 screw compactor (screw press) manufactured by Avermann Maschinenfabrik.

This screw compactor features:

- A compact design, and hence increased flexibility and accelerated retooling

- 15 kW drive motor

- Shaft bearing instead of live ring bearing, hence

- Load capacity increased by up to 200%

- Up to 4 times longer lifespan

- Maintenance free shaft seal

- Reinforced worm shaft

- Optional remote operation

- Particularly suitable for wood packaging, cardboard (PPK) and PET bottles

- Highest visibility level in interchangeable container

- Capacity of up to 8 t in a 32 m²

- Interchangeable container

- Cost savings thanks to reduced transportation