OptiCut

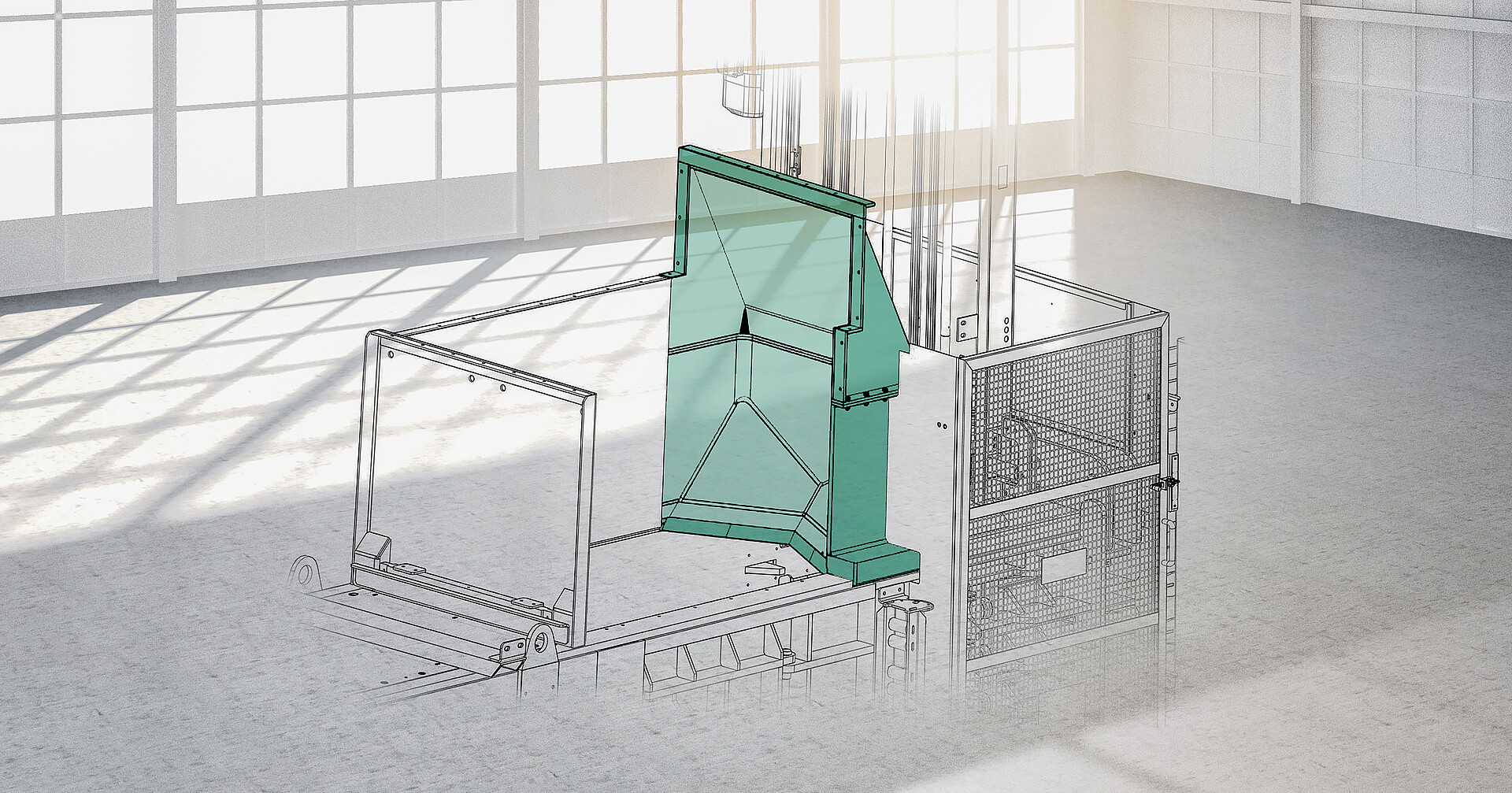

More throughput and efficiency for horizontal balers

The newly developed, patented “OptiCut” cutting system marks the start of a new era in the construction of horizontal balers. It eliminates the need for a stamper plate and also increases throughput to an unprecedented level of 50 to 100 percent. This quantum leap forward in environmental technology is particularly beneficial to users who rely on extreme throughput figures with maximum reliability. Because, in addition to the reduction in cutting pressure, overall hydraulic and mechanical loading is significantly reduced due to a homogenous cutting process. This is made possible thanks to an optimally dimensioned expansion space for the material during the cutting process. The OptiCut system is available both for Avermann horizontal balers as well as for retrofitting to third-party units.

OptiCut - More throughput and efficiency for horizontal balers

Until now it was not possible to show the exact pressing process of our horizontal balers because the baler body consists of thick and massive steel and you are not able to see through it. Luckily, we found the perfect solution to this problem: In cooperation with the company Drehteam in Osnabrück we designed an animated film about our high performance horizontal baler AVOS 1810 with OptiCut and special press ram.

The newly developed, patented “OptiCut” cutting system marks the start of a new era in the construction of horizontal balers. It eliminates the need for a stamper plate and also increases the throughput of the press to an unprecedented level of 50 to 100 percent.