Horizontal baler type AVOS 1410 BRH

The long-distance runner – for reliable continuous operation

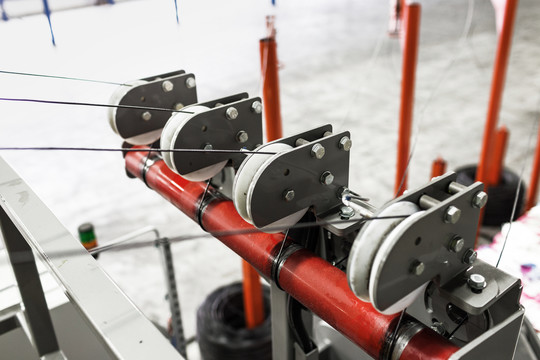

Count on maximum stability when pressing waste and recyclables in continuous operation! The horizontal baler type AVOS 1410 BRH with 22 kW drive capacity and 500 kN press force is the optimal machine where continuous performance in long-term operation is required, for example in central warehouses and dispatch warehouses working in three shifts. The press is equipped with a hydraulically controlled binding unit and a press ram with hardened steel rollers on HARDOX guide rails.

In addition, heating and cooling elements for the hydraulic oil permit continuous use of the baler, even in extreme temperature ranges. The press ram is driven by means of an energy-saving, performance controlled axial piston pump. For higher requirements in terms of throughput rate, there is the machine type AVOS 1410 BRHF with a more powerful hydraulic system.

The fully automated horizontal baler AVOS 1410 BRH is perfectly suitable to compact cardboard, paper, plastics and other recyclable materials. State of the art technology according to the C standard for horizontal balers published in 2013 (DIN EN 16252).

All specifications are approximate values and the final, constructive determination reserved.